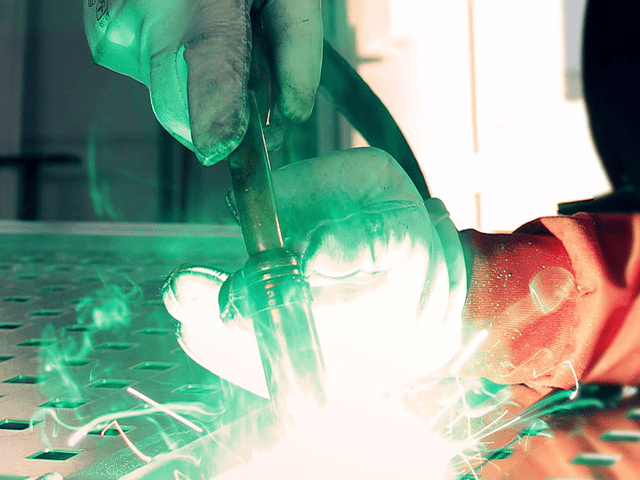

Research by the International Agency for Research on Cancer (IARC) indicates that exposure to welding fumes can cause a number of health conditions including lung cancer, kidney cancer, COPD, asthma, metal fume fever, siderosis, stomach ulcers, renal damage, and neurological effects similar to Parkinson’s disease (Manganism).

All welding fume from all types of metal should be treated as capable of causing cancer, and the IARC has reclassified all welding fume, including fume from mild steel welding, as Group 1 carcinogenic to humans.

How does this affect you?

All businesses undertaking welding activities should ensure all personnel are protected from the inhalation risk of welding fumes by providing effective engineering controls for risk mitigation. For example, Local Exhaust Ventilation (LEV) when provided and correctly applied, will control fumes and gases arising from welding activities.

Where engineering controls are not sufficient to control all fume exposure, adequate and suitable respiratory protective equipment (RPE) is also required to manage risk from the residual fume, including welding outdoors. You should ensure welders are suitably instructed and trained in the use of these controls.

Regardless of duration, the UK HSE will no longer accept any welding undertaken without suitable exposure control measures in place, as there is no known level of safe exposure. Risk assessments should reflect the change in the expected control measures.

What can we do to assist you?

Element has one of the largestOccupational Hygieneteams in the UK, comprising of a range of technically competent and qualified staff.

Our experienced team of qualified occupational hygienists can assist in:

- Devising an air monitoring strategy

- Personal welding fume monitoring

- Assessing your control measures

- Examining and testing of your LEV systems

- Fume control advice

We undertake air monitoring using the latest equipment, which is calibrated before and after sampling in accordance with ISO 10882 ‘Health & Safety in Welding and Allied Processes - Sampling of Airborne Particles and Gases in the Operator’s Breathing Zone.’ All sample analytical work is undertaken at UKAS accredited analytical laboratories that participate in the AIR PT scheme.

We can also conduct a thorough examination and testing ofLEVsystems following the HSG258 and carry out risk assessments to determine if all engineering controls are used correctly.

For more information on welding fume exposure monitoring and how we can assist you, pleasecontact us today.

Welding Fume Safety - Everything You Need To Know

Read our articleon Welding Fume Safety to discover more about risk assessment, exposure monitoring and control measures. Welding fume safety is critically import since anyone exposed is at risk of developing occupational asthma, cancer, irritation of the breathing airways, metal fume fever, pneumonia and other illnesses.

Related Services

Local Exhaust Ventilation (LEV) Equipment Testing

Element provides a comprehensive range of LEV testing services across a range of extraction systems, in accordance with HSG258 guidelines, to help you make certain that the workplace is safe and compliant.

Whole Body and Hand-Arm Vibration Assessments

Element has a track record in delivering hand-arm vibration syndrome (HAVS) and whole-body vibration (WBV) assessments in the workplace to make certain your employees receive the best possible care.

Noise in the Workplace

Element's experts have years of experience in carrying out on-site noise assessments. All assessments undertaken by our experts are qualified through the Institute of Acoustics and BOHS, in accordance with the UK HSE guidance L108 "Controlling Noise at Work."

Workplace Air Monitoring

188金宝搏手机端元素的经验丰富的合格occ团队upational hygienists specializes in delivering a range of workplace air monitoring services for use within a diverse range of operating environments.